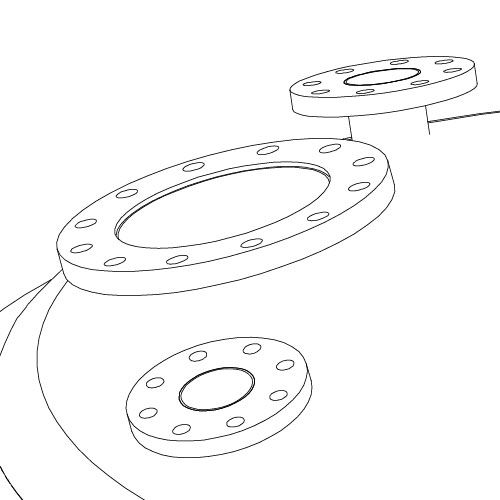

Stainless Steel Chemical Reactors

We design and custom-build industrial chemical reactors, tailored to facilitate various types of chemical reactions.

Can’t find a chemical reactor on the market that meets your specific needs?

Our vessels are customized based on the chemical properties of the substances involved and the nature of the reactions they facilitate.

Features

Chemical reactors are essential equipment for containing chemical reactions within a steel tank.

Their design and structure allow for optimal spatial arrangement within industrial plants.

We offer customization in terms of size and types of accessories.

Reactors can be equipped with mixing systems, featuring impellers tailored to the type of product being processed.

We can integrate a special system to monitor the internal temperature of the product.

These reactors are suitable for various chemical processes and treatments.

Welding

Welding:

TIG/Argon welding is performed to ensure a longer container lifecycle.

Protection:

The welds are all protected with reverse gas to ensure high standards of quality and durability.

Intended use

Chemical and Pharmaceutical

- formulating products such as detergents, cleaners, thinners, etc.

Cosmetic

- Creating products in liquid or semi-liquid form.

SERVICES ALWAYS GUARANTEED

- Bespoke design in all cases: following your specific project, designing a fully customized solution just for you, or starting with an on-site visit to your factory to take measurements and respect the overall dimensions, heights, and layout of your company.

- Plasma cutting: for sheet metal and pipes.

- Micro-bead blasting treatment: to achieve a uniform satin finish on every part, from flat surfaces to fittings.

- On-site construction of the tank at your premises, if required.

- Final inspection in accordance with the law and following all safety instructions.

- Organization of transport to your plant, even for oversized silos, for which exceptional transport is required.

- On-call maintenance.

- Timeliness in replies and adherence to delivery times.

Contact us

We are at your disposal, below you will find our contact information.

We are waiting for you.

Come by, call, write

Complete the form

All fields are required.

CA Inox srl - Via Vallecchia, 17 - 37024 Negrar di Valpolicella VR

P.IVA IT04856140233 - REA VR - 451479 - Cap.Soc. € 10.000 iv